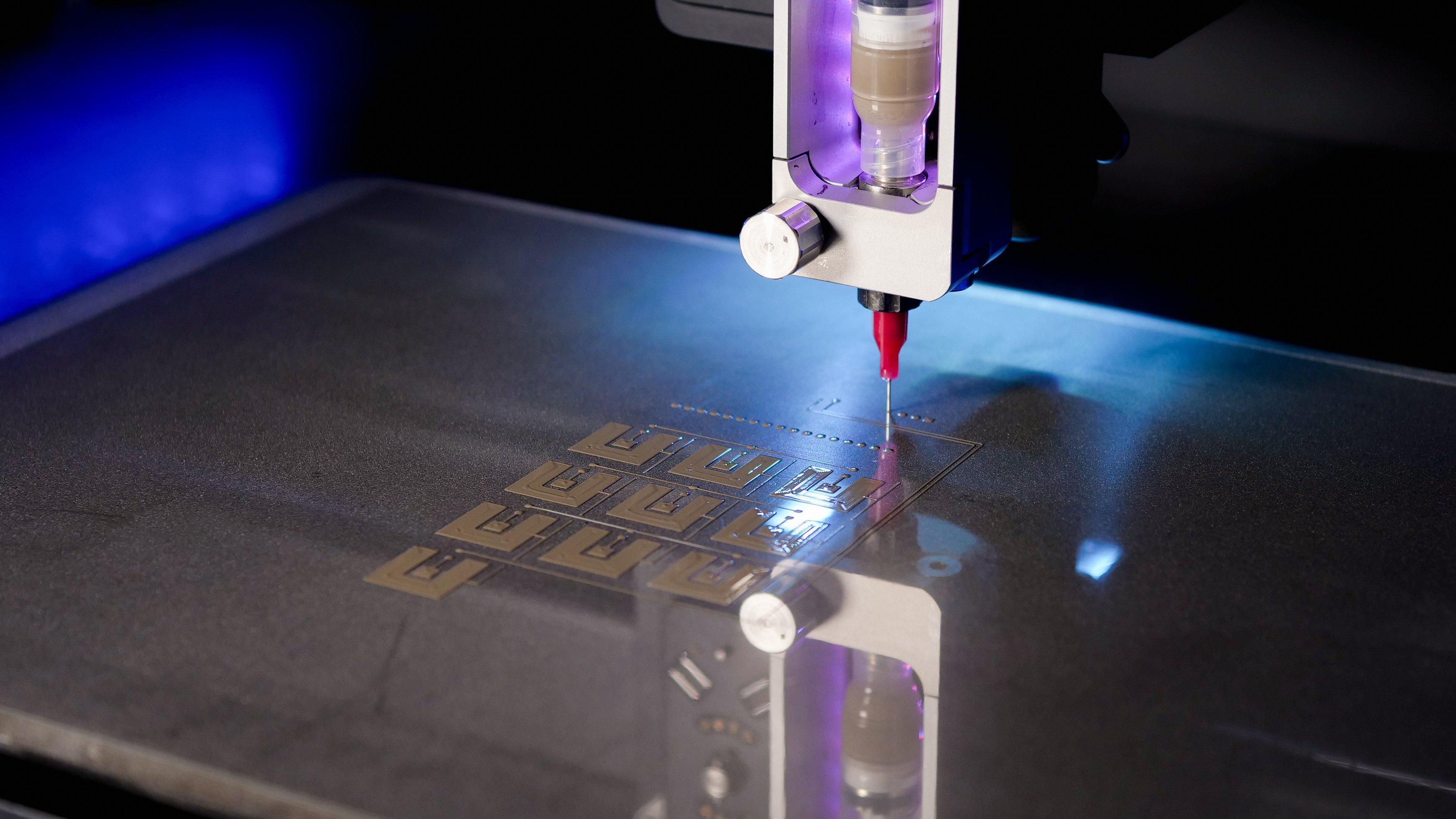

The future of printed electronics

Accelerate research and development by 90%. Experiment with novel materials ranging from 1,000 to 1,000,000 cps in viscosity, achieving a resolution as fine as 100 µm. Print your groundbreaking designs on flexible, soft, and stretchable substrates.

From bendable LED screens to printed paper batteries, NOVA enables you to unlock new frontiers in prototyping flexible hybrid electronics, as well as test novel materials.

Unlock new opportunities

Explore what’s possible with printed electronics.

Streamline research and development

Change designs on the fly and get immediate feedback.

Total material freedom

Experiment with a wide range of substrates and screen-printable materials.

No experience required

The intuitive user experience alleviates internal training challenges.

NOVA Specifications

To provide more context, here are the technical specifications that enable NOVA to support all the amazing projects.

| Ideal for |

|

| Print area | 220 mm x 300 mm 8.7” x 11.8” |

| Dispensing technology | Direct ink write (DIW) |

| Dispensable materials | Solder paste, silver, copper, carbon inks, and other screen printable materials |

| Minimum trace width | 0.1 mm* |

| XYZ resolution** | 2.5 µm x 7 µm x 1.25 µm |

| Material temperature control | Up to 40°C |

| Substrates |

|

|

*Dependant on material properties and nozzle size |

|

Who’s using Voltera NOVA?

/NextFlex.png?width=1195&height=1195&name=NextFlex.png)

/ACI.png?width=1195&height=1195&name=ACI.png)

/University%20of%20Southern%20California.png?width=1195&height=1195&name=University%20of%20Southern%20California.png)

/University%20of%20Hawaii.png?width=1195&height=1195&name=University%20of%20Hawaii.png)

/Duke%20University.png?width=1195&height=1195&name=Duke%20University.png)

What we've been able to do with NOVA is print carbon nanotube inks and get field-emitted electrons. (...) Working with NOVA has been fascinating. We've been able to construct devices that we would not be able to do conventionally without expending enormous time and resources.

Alex Kashkin, Graduate Researcher, Velásquez Group at MIT

What can NOVA do?

A ceramic PCB that utilizes an alumina substrate, offering enhanced mechanical strength and superior thermal conductivity, suitable for high-performance electronic applications such as high-power transistors.

Substrate

Alumina

Inks

NovaCentrix HPS-FG57B Silver Flake Ink

NovaCentrix HPR-059 Carbon Ink

Nozzle

Subrex 150 µm micro precision nozzle

Print time

About 35 minutes

A strain gauge crafted on an FR4 substrate, known for its dielectric strength and moisture resistance, making it a robust choice for sensing applications such as measuring mechanical deformation in aerospace or automotive systems testing.

Substrate

FR4

Ink

NovaCentrix HPR-059 Carbon Ink

Nozzle size

Subrex 150 µm micro precision nozzle

Print time

About 15 seconds

A force sensitive resistor (FSR) sensor that employs a flexible PET substrate, ensuring its adaptability and durability in flexible applications that require real-time force measurement, such as in interactive devices.

Substrate

PET

Ink

ACI RD0142A Conductive Ink

Nozzle

Subrex 100 µm micro precision nozzle

Print time

About 20 minutes

An electrode configuration printed on a glass microscope slide, offering high transparency and excellent surface stability ideal for applications in electrochemical analysis, biosensors, and scientific research.

Substrate

Glass microscope slide

Ink

Creative Materials EXP2656-186 Ink

Nozzle

Nordson EFD 100 µm Optimum chamfered tip

Print time

About 5 minutes

.jpg?width=288&height=162&name=application_flexArduino%20(4).jpg)

An example of flexible hybrid electronics (FHE) that integrates functionality with versatility. These types of circuits can be used in applications where flexibility and durability are paramount, such as wearable health monitors.

Substrate

Kapton

Ink

ACI RD0142A Conductive Ink

Nozzle size

Nordson EFD 100 µm Optimum chamfered tip

Print time

About 15 minutes

©2024 Voltera Inc.![]() All rights reserved.

All rights reserved.